What kinds of lapel pins need epoxy adding?

Epoxy adding is to add a layer of transparent resin on the surface of the lapel pin, which is used to protect and beautify the lapel pin. It is a common process of making lapel pin. Whether a badge requires epoxy or not, is determined by the crafts of the lapel pins.

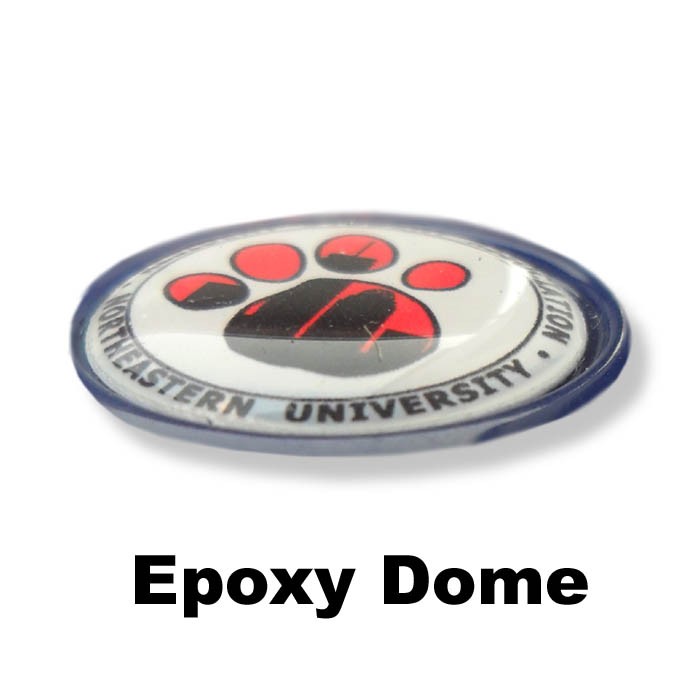

The printing lapel pins need to add epoxy to protect the surface of the lapel pin. The common printing lapel pins are silk screen printing lapel pins and offset printing lapel pins, collectively named epoxy lapel pins.

The hard enamel lapel pins and imitation hard enamel lapel pins do not need to add epoxy since for these two kinds of colors, after grinding and stoning, the surface becomes smooth and solid, and generally the color won’t fall apart.

The soft enamel lapel pins generally don’t need to add epoxy. The biggest characteristic of the soft enamel lapel pin is the strong line sense, if adding the epoxy, it will have no concave-convex feeling. But some customers would like to add epoxy since if the epoxy is properly used, it would make the soft enamel lapel pins look like imitation hard enamel lapel pins.