Custom 3D coins can be a great way to commemorate special events or achievements. They offer a unique and personalized way to recognize outstanding work or dedication. 3D coins are made using the latest printing technology to create detailed designs that are both durable and long-lasting.

The first step in creating custom 3D coins is to design the artwork. This can be done by a professional designer or by someone with graphics skills. Once the artwork is ready, it is sent to the coin manufacturer who then produces a mold of the design. This mold is then used to create the 3D coins using a combination of advanced printing techniques and precise molding techniques.

When creating your custom 3D coins, be sure to choose a reputable and experienced manufacturer. They should be able to provide you with a range of options and materials to ensure your coins are of the highest quality. Custom 3D coins come in a range of sizes and finishes, so be sure to select the one that best suits your needs

For Custom 3D coins, we would suggest our customer to process by die-casting and antique finished plating. The die casting process can make outstanding 3D effects and irregular outer shapes. The biggest difference between 2D and 3D effects on coins is that 2D design is with flat metal lines, but the metal line on 3D design is with curved surface, viewing the products from side will makes this easier to understand.

The 3D coins with antique finished plating can highlight the relief details with less reflection and all of the design details can be looks clearer.

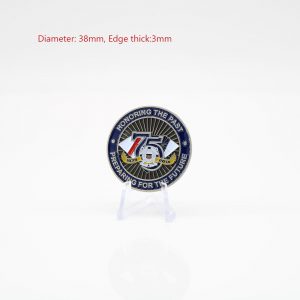

Specification:

Material: Copper, brass, iron, zinc alloy, pewter, etc.

Colors: Hard Enamel / Imitation Hard Enamel / Soft Enamel / Silk Screen / Offset Printing / Transparent / Glow in Dark or no colors

Standard Size: Customized size.

Polishing: All the custom medals with 3 sides polishing. (Front / Back and Edge)

Plating Finish color: Silver, Gold, Bronze, Copper, Nickel, Rhodium, Chrome, Black Nickel, Dyeing Black, Antique Gold, Antique Silver, Antique Copper, Satin Gold, Satin Silver, Dual Plating Color, Spray Painting, etc.

Order Information:

MOQ: no minimum

Package: OPP Bag

Payment: T/T / PayPal / Credit Card

Delivery: Need to confirm again when customer approved the artwork / samples.

Lead Time: 15-20 days. lead time is negotiable.

On The Production Side:

Our in house computerised engraving & printing facility allows us to offer a superb Engraving & printing option for logos and messages with an extremely quick turnaround time.

On the Equipment and Technology Side:

We own professional staff and advanced equipments, including 15 CNC die carving machines, 1000T X 2; 500T X 2; 300T X 2 Oil hydraulic press, 4 Die casting machines and various punching machines.R & D and production capacity.More than 15 years experience in R & D and design, automation, cost saving.

Our commitment to you is great service and excellent quality products, resulting in satisfied customers. Thank you for giving us the opportunity to make your next project a huge success. I guarantee you will love us.